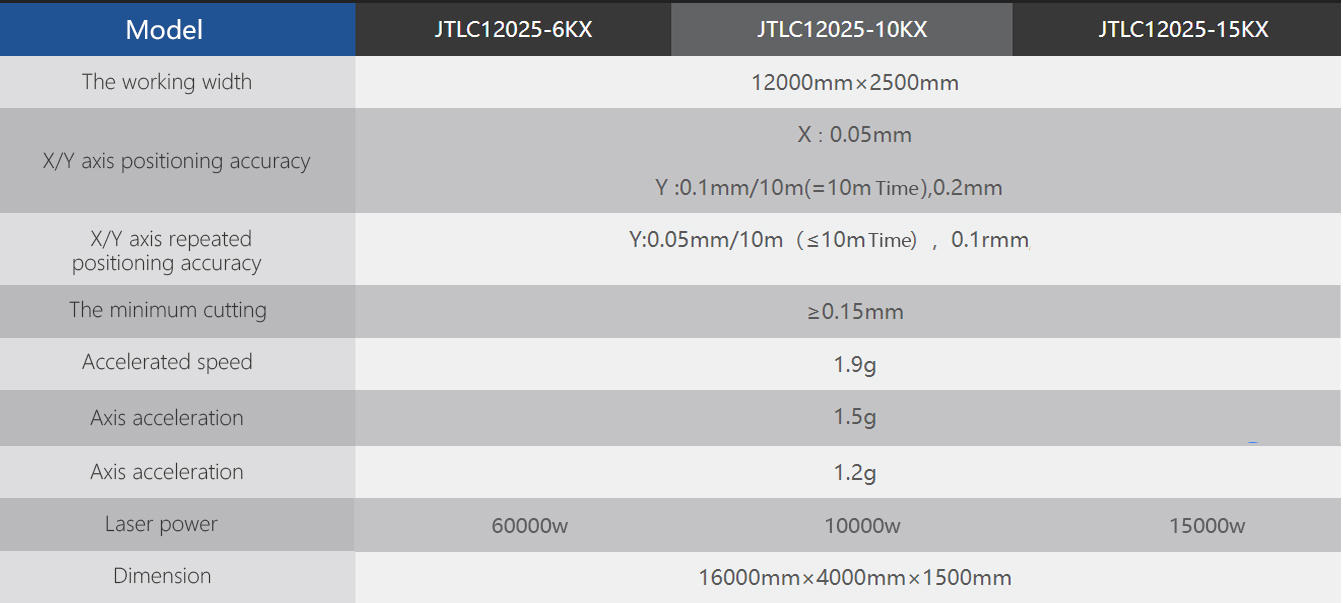

Double Pallet Laser Cutting Machine

Model No.: JLC1225HS

LC series large-format surface high-speed laser cutting machine has a 12-meter large-format surface platform, the cutting range is larger and wider, with intelligent system, more convenient operation, greatly reduce operating costs, simplify labor, can be used in industrial environment; Long service life, high machining accuracy, fast speed; High energy conversion efficiency, can realize intelligent, automatic, flexible operation.

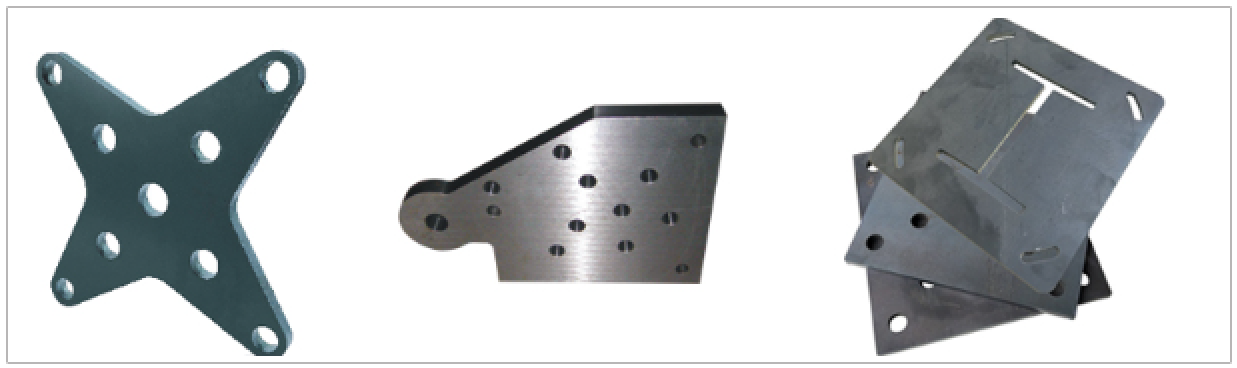

1, using gantry double drive structure, high precision reducer, rack and pinion and linear guide rail, smooth transmission, fast acceleration, high positioning accuracy.

2. One-button calibration, automatic edge finding, automatic typesetting, leap-over and other powerful technical functions, simplify the operation process. Patented machine design, good cutting quality, small thermal deformation, cutting surface is smooth, smooth and beautiful.

3.The use of professional CNC cutting software, random design of all kinds of graphics or text, flexible processing, simple operation

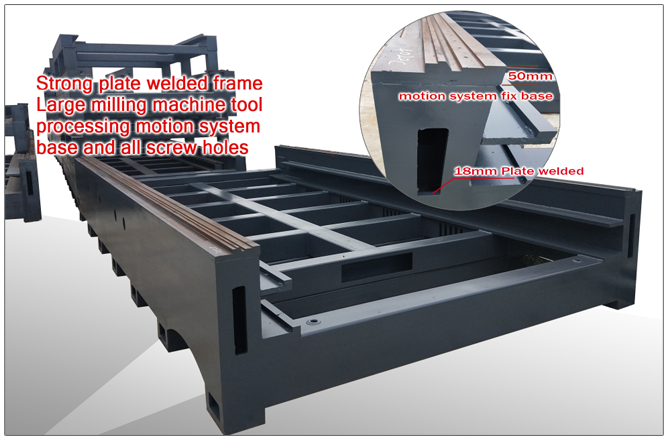

Product structure The bed adopts integral welding structure. After eliminating the internal stress by annealing, roughing and finishing by two times vibration aging treatment, the stress caused by welding and machining can be better solved, so as to greatly improve the performance of the machine tool. X, Y, Z axis adopts Germany imported servo motor, equipped with high rigid precision reducer, precision gear and rack, high precision linear guide, such as efficient transmission mechanism, effectively ensure the transmission accuracy, beam with light casting structure, the stress relief annealing after rough machining, the secondary vibration aging treatment of metal finishing, to better solve the stress of the casting process to produce, Greatly improve the stability of the machine tool. | |

| ---The beam adopts light casting structure, rough machining after annealing to eliminate internal stress, and finishing after secondary vibration aging treatment. The stress caused by casting processing is better solved and the stability of the beam is improved. |

Application field and cutting ability 1, suitable for cutting space: a two-dimensional plane cutting; 2, application industry, food machinery, kitchen utensils and appliances, sanitary ware, elevator manufacturing, household appliances, food machinery, textile machinery, tools, processing, automotive, decorative advertising, aerospace, Marine, engineering machinery, locomotives, forestry machinery, electrical manufacturing, petroleum machinery, laser external processing machinery manufacturing industry such as the service; 3, cutting material: carbon steel, stainless steel, aluminum alloy, brass, copper, pickling plate, silicon steel plate, electrolytic plate, galvanized sheet, titanium alloy, manganese alloy; | |

|