JTLC 3015 3D Five Axis Laser Cutting Machine

Main technical indicators of the machine tools

Equipment model | JTLC 3015 |

Journey | |

X-axis travel | 3000mm |

Y-axis stroke | 1500mm |

Z-axis stroke | 625mm |

A-axis travel | ±135° |

A-axis travel | ±n×360° |

W-axis stroke (following axis) | ±11mm |

Accuracy | |

X / Y / Z, axis positioning accuracy | ±0.05mm |

Repeat positioning accuracy of the X / Y / Z axis | ±0.05mm |

A / C axis positioning accuracy | 0.03° |

A / C axis repeat positioning accuracy | 0.01° |

Velocity | |

X, Y, Z-axis maximum positioning speed | 80m/min |

X, Y, Z axis maximal synthesis velocity | 144m/min |

A / C axis maximum positioning speed | 540°/s |

X, Y, Z axis maximum cut acceleration | 0.5G |

X, Y, Z axis maximum localization synthesis acceleration | 1.2G |

A / C axis maximum acceleration | 3600°/s² |

Work Platform | |

Work Platform | Flat cutting range :3000x1500mm

Maximum 3 D cutting range, length, width and height: 2360x860x680mm |

Power parameters | |

number of phases | 3 |

Power supply rated voltage | 380V |

frequency | 50Hz |

Protection level of main power supply | IP54 |

Weight and size | |

Host weight | 12000kg(Including workbench 2000kg) |

Equipment footprint (complete machine) | long × wide × high:6100×6000×3900mm |

JTLC 3015 Three-dimensional five-axis laser cutting machine is a multi-angle, comprehensive cutting, flexible processing more flexible, specifically for sheet metal and mold manufacturing industry development of laser processing equipment, widely used in automotive manufacturing, aerospace, shipbuilding, engineering machinery, mold, fitness equipment, kitchen utensils and appliances, and so on. It can meet the cutting hole and trimming problems of plate cutting and 3 d workpiece, which is characterized by good openness, high precision, fast speed, good dynamic performance and high cost performance. JTLC 3015 Using cantilever structure, bed body adopts overall welding processing molding, high rigidity high dynamic response beam, and using high precision linear rail and gear rack motor drive, has the characteristics of light weight, good dynamic response, transmission parts such as gearbox, rail and gear rack using the countries, internal and external famous brands, machine cantilever overall structure gives its excellent openness and space utilization. The transmission mode of gear and rack ensures the high-speed positioning, fast dynamic response and good stability of the equipment. Bed body and other main parts after full artificial effect, can be lifted as a whole, with strong stiffness, good stability, convenient installation and other characteristics.

Main configuration of products

Name | Brand | characteristic |

Machine tool ontology |

JTLC 3015 | Using integrated integral welding processing molding, can be overall lifting, With strong stiffness, good stability, convenient installation and other characteristics |

numerical control system |

The origin of Europe Fagor 8070 laser | Internationally renowned numerical control system, secondary deep development. |

laser | Rui ke 3000w | Internationally renowned fiber laser |

Cut the head |

Jiatai self-developed 3 D laser cutting head | Light weight, fast speed, can achieve infinite rotation, high dynamic Floating shaft, with anti-collision function |

Work Platform | Provide 2 D or 3 D cutting platforms | |

water chilling unit | With the fly | Double temperature / matching |

Dust removal facilities | Jia Tai supporting | Efficient environmental protection |

Air filtration device | Air filtration device |

standard configuration |

stabilized voltage supply | Katay standard 30KVA | For laser use |

CAM programming package software | Germany Tebis | Dedicated 3 D offline programming software |

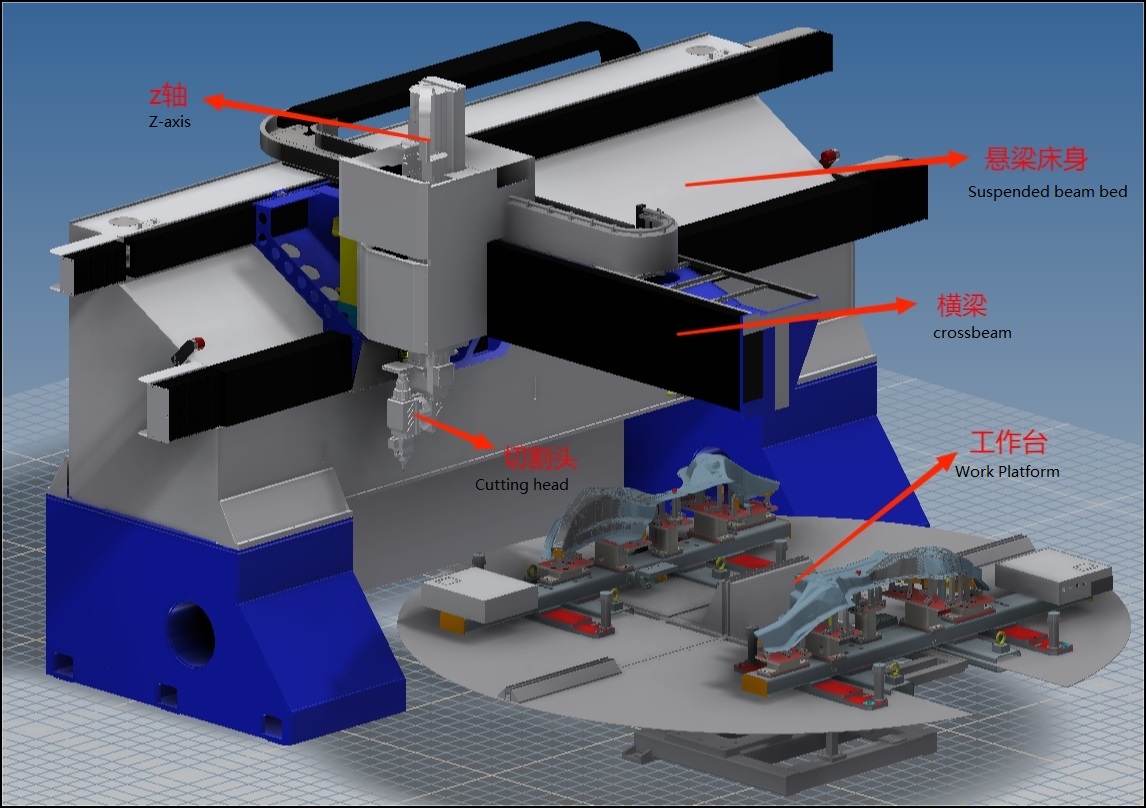

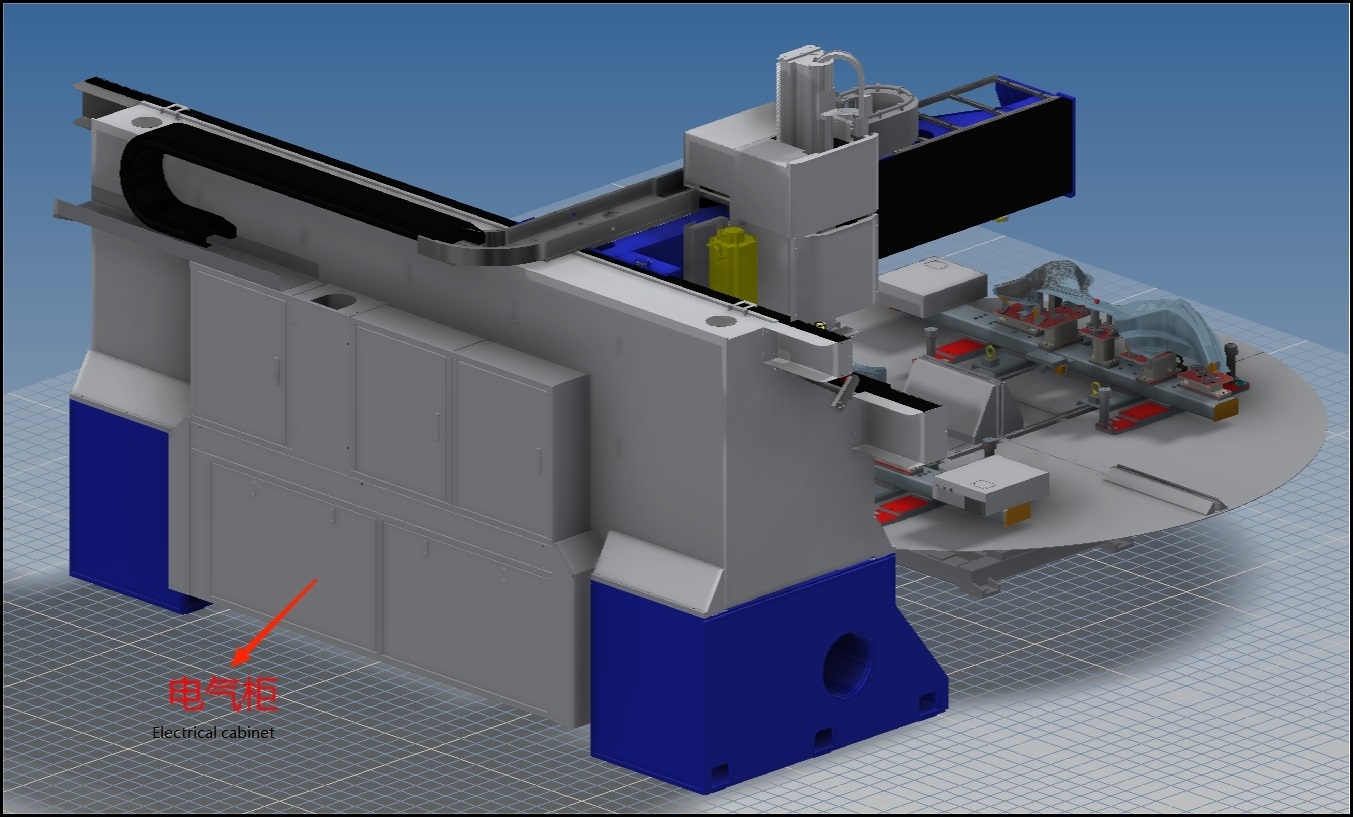

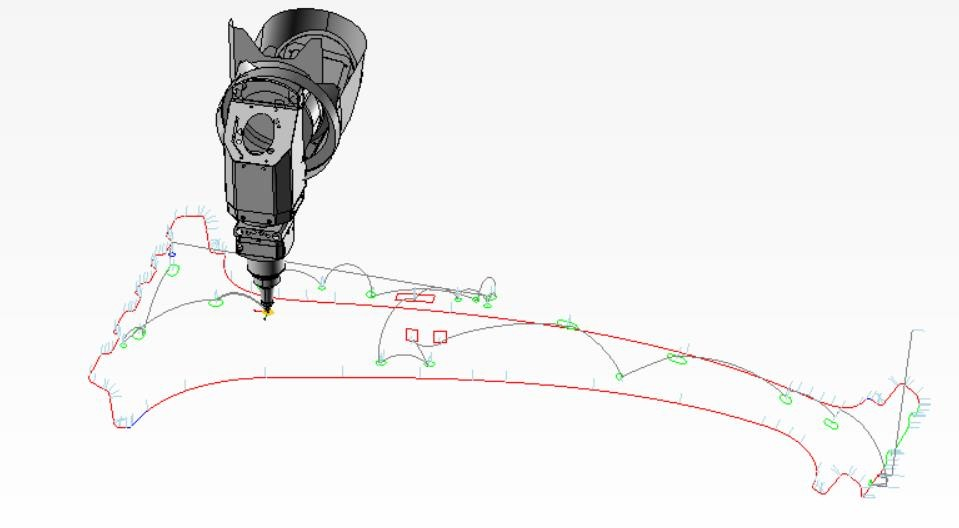

Introduction to mechanical structure

Machine host by cantilever bed body, beam, Z axis, cutting head, workbench and other main components, X, Y, Z shaft are gear rack drive way, maximum 3 d cutting range 2360x860x680mm, the bed adopts integrated welding processing molding, but overall hoisting, with strong stiffness, good stability, convenient installation, etc.

Machine host by cantilever bed body, beam, Z axis, cutting head, workbench and other main components, X, Y, Z shaft are gear rack drive way, maximum 3 d cutting range 2360x860x680mm, the bed adopts integrated welding processing molding, but overall hoisting, with strong stiffness, good stability, convenient installation, etc.

The machine has three linear axes X, Y and Z. Are driven by high-torque AC servo motors.

The cutting head has 1 rotation axis, 1 swing axis and 1 following axis.

The cantilever machine tool is well open and covers less space.

Cutting bench can be plate cut or 3 D cutting range of 3000x1500mm.

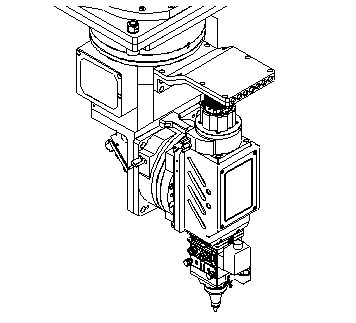

A 3 D laser-cutting head

The cutting head is equipped with 1 rotation axis, 1 swing axis and 1 following axis, all axes adopt compact structure, small power loss, high fast shift speed, high acceleration and high speed. Rotation axis C axis is a rotation axis that can be rotated 360 in the vertical direction, which means it can rotate around its own axis, to ensure that the cutting head is not restricted in performing various complex trajectory movements. The wing axis B can swing ± 135 in the vertical direction. High localization of the RTCP function. Authorized five-axis difference is not software, loading high rigidity cutting head, can achieve the spatial fixed point precision within the error range of 0.1 mm. Effectively improve the cutting accuracy. There is also a special high dynamic following axis W axis (± 11mm), which is used to automatically compensate for the error between the actual size of the surface of the part and the theoretical size caused by elastic deformation, so as to ensure that the distance between the lens on the cutting head to the surface of the workpiece is constant. The function of the moving shaft is to achieve the high flexibility of the machine tool and the rapid positioning and perforation on the workpiece.

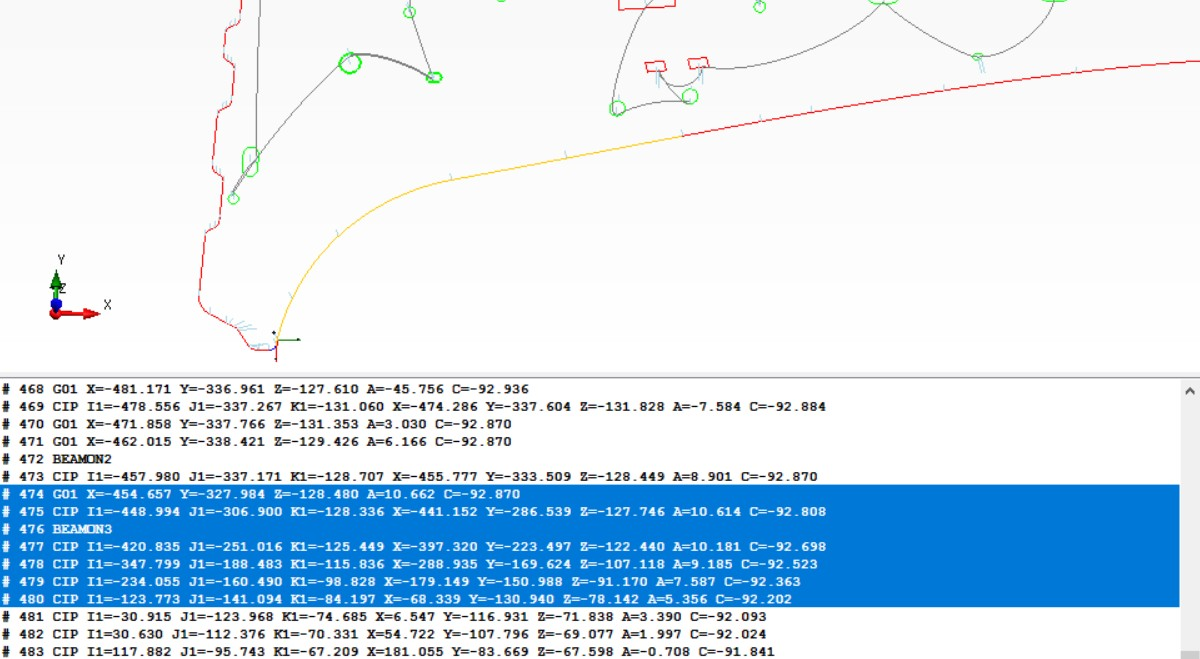

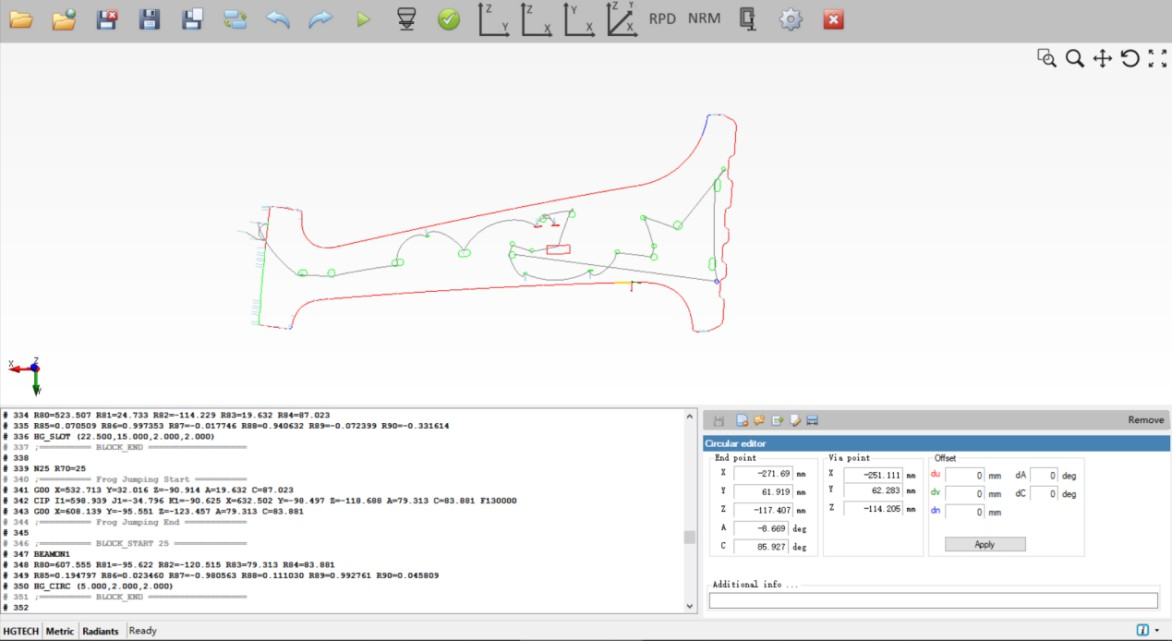

3D-EDIT modified the software online

The 3D-EDIT overall interface is simple and clear, covering the most comprehensive features with the most streamlined interface. Each button has unusual functions, which make it easier for the operator to use. Make it easier for beginners to learn.

Offline programming software programming, manual teaching programming or pure manual programming NC program, the software can be recognized. And take the cutting program as the benchmark, the reverse guide program, display the cutting path, make and save the change on the basis of the original program, accurate change, reduce the error rate. The cutting path after the software is intuitive, different cutting parameters at a glance.

Offline programming software programming, manual teaching programming or pure manual programming NC program, the software can be recognized. And take the cutting program as the benchmark, the reverse guide program, display the cutting path, make and save the change on the basis of the original program, accurate change, reduce the error rate. The cutting path after the software is intuitive, different cutting parameters at a glance.

Whether the hole position, aperture, and other hole parameter modification or the side line position modification are convenient and effective, the coordinate system is clear at a glance, the modification direction is flexible. Real-time box selection program segment, real-time selection on the cutting path.

Whether the hole position, aperture, and other hole parameter modification or the side line position modification are convenient and effective, the coordinate system is clear at a glance, the modification direction is flexible. Real-time box selection program segment, real-time selection on the cutting path.