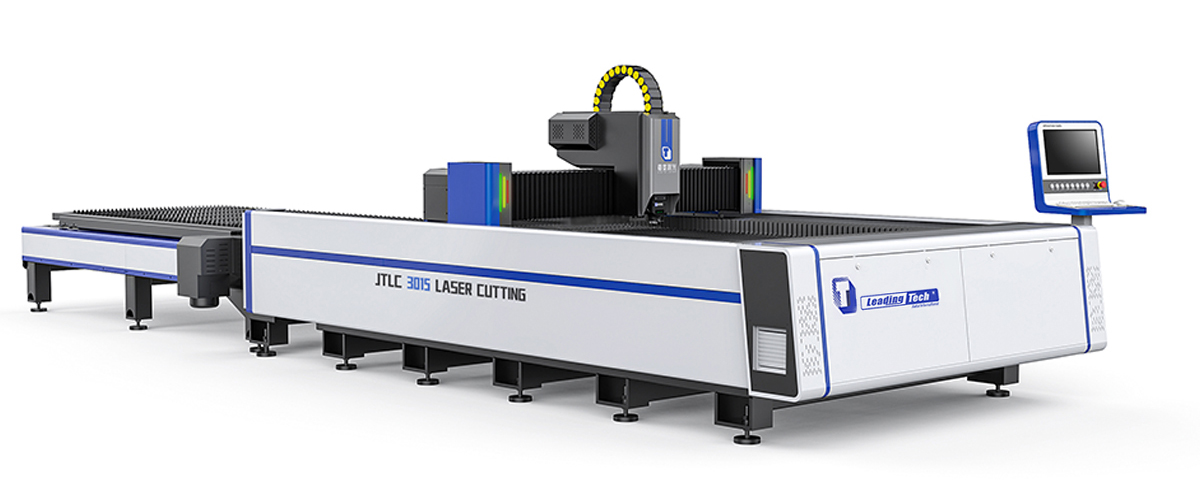

Double Pallet Laser Cutting Machine

Model No.: JLC3015LD

This model adopt split type design, the laser source and electronic control unit install separated with working table, user can keep electronic control unit and laser source in separate space easily, avoid machine’s sensitive parts influence by bad environments, such as metal dust, corrosive gas/fogs, high temperature,electromagnetic interfere etc., this design can be working at some special environments.

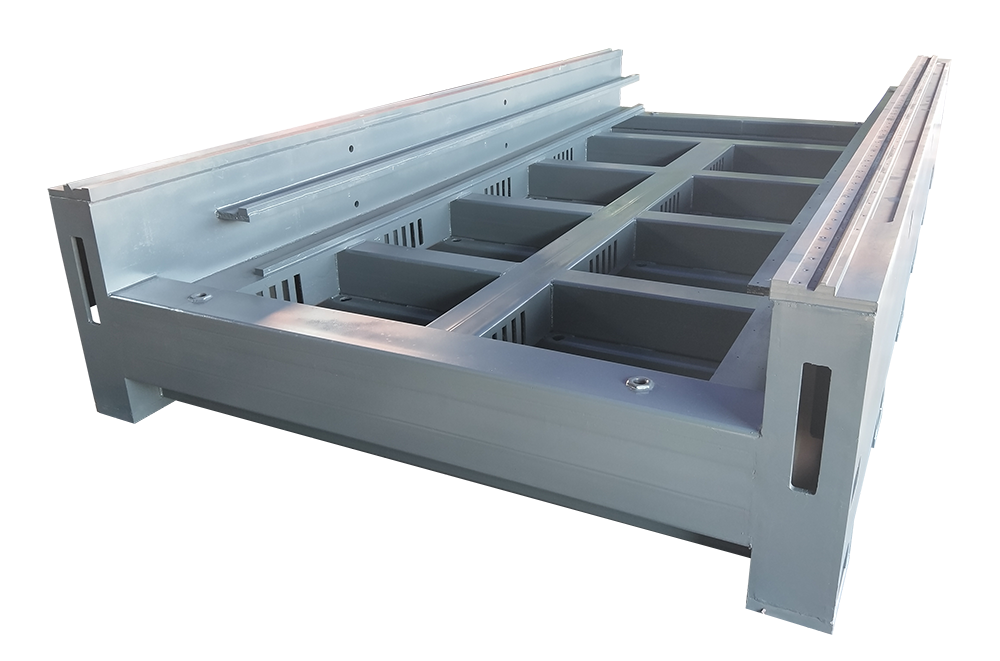

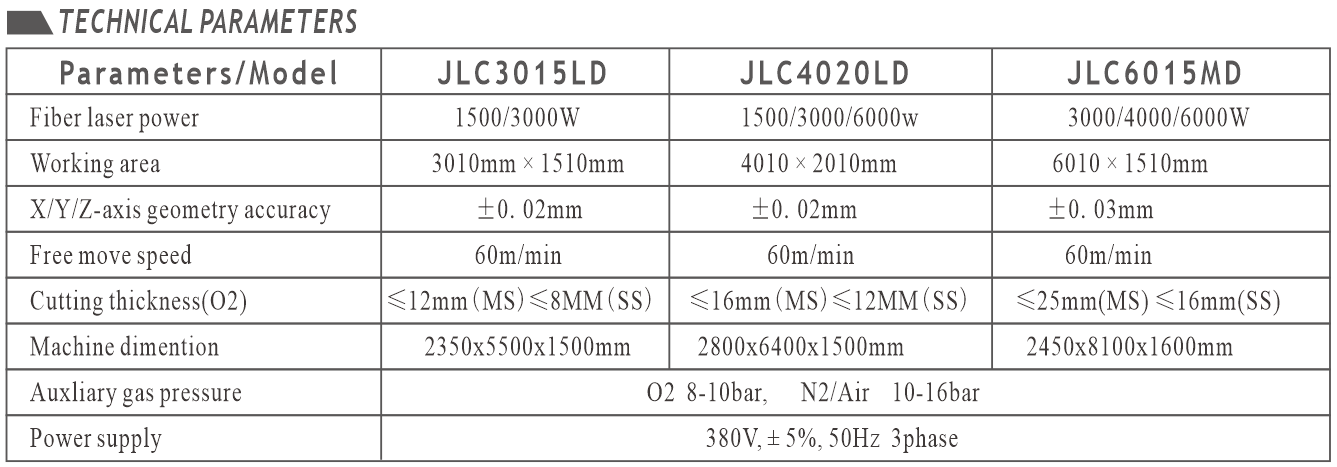

Large milling machine machining movement system The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting. |

|

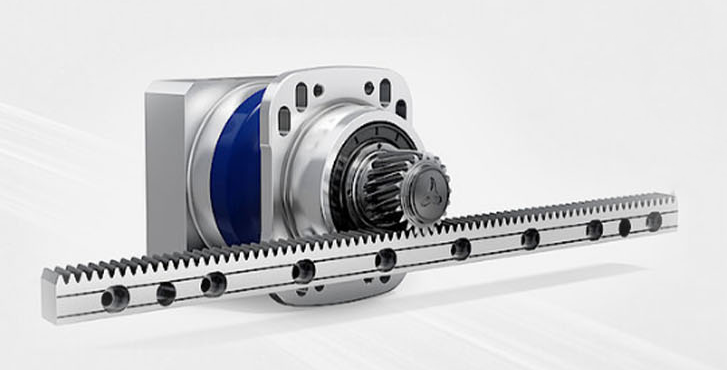

The aircraft with imported ac system driven and imported transmission system, machine tool motion mechanism adopts imported gear rack drive, linear guide, ensure the high speed, high precision, high reliability;Rack and guide rail seal protection device used to prevent oil free friction movement and dust pollution, improve the service life of the transmission parts, ensure the accuracy of machine tool movement;Laser cutting head import capacitance non-contact high tracking system configuration, responsive and accurate, and avoid cutting head and processing plate collision, and can ensure the cutting focus position, ensure the quality of cutting stability; | |

Lathe bed use whole welded structure. After stress relief annealing for rough machining, then through the secondary vibration aging treatment of metal finishing, can better solve the stress produced by welding and machining, thus greatly improve the performance of machine tool. X, Y, Z axis adopts Germany imported servo motor, equipped with high rigid precision reducer, precision gear and rack, high precision linear guide, such as efficient transmission mechanism, effectively ensure the transmission accuracy, beam with light casting structure, the stress relief annealing after rough machining, the secondary vibration aging treatment of metal finishing, to better solve the stress produced by casting machining, greatly improving the machine The stability of the bed |

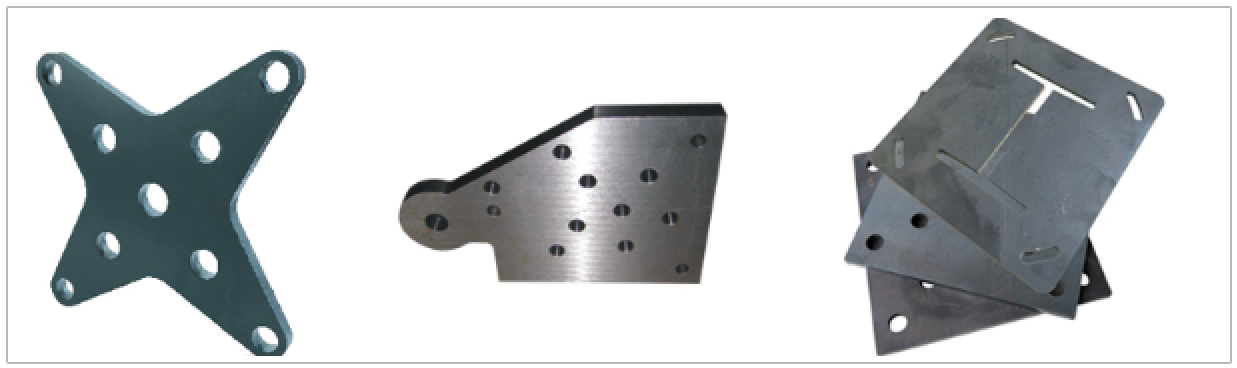

Application field and cutting ability 1, suitable for cutting space: a two-dimensional plane cutting; 2, application industry, food machinery, kitchen utensils and appliances, sanitary ware, elevator manufacturing, household appliances, food machinery, textile machinery, tools, processing, automotive, decorative advertising, aerospace, Marine, engineering machinery, locomotives, forestry machinery, electrical manufacturing, petroleum machinery, laser external processing machinery manufacturing industry such as the servie; 3, cutting material: carbon steel, stainless steel, aluminum alloy, brass, copper, pickling plate, silicon steel plate, electrolytic plate, galvanized sheet, titanium alloy, manganese alloy; |

|

1.Quality Control Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery. | |

2.OEM Service Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required. |