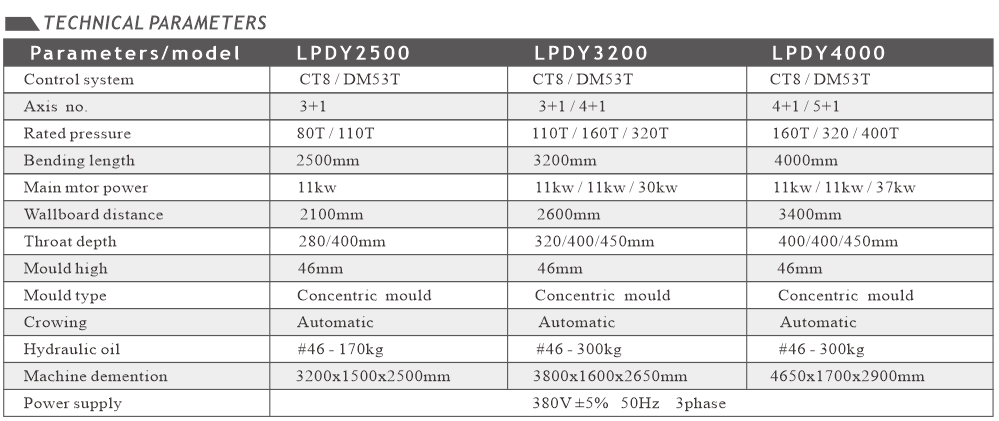

CNC Bending Machine

Model No.: LPDY-110T/3200

Technical parameters with CNC system

A、 Machine model and name

1、 Model:LPDY-110T/3200

2、 Product name:CNC bending machine

B、Machine use

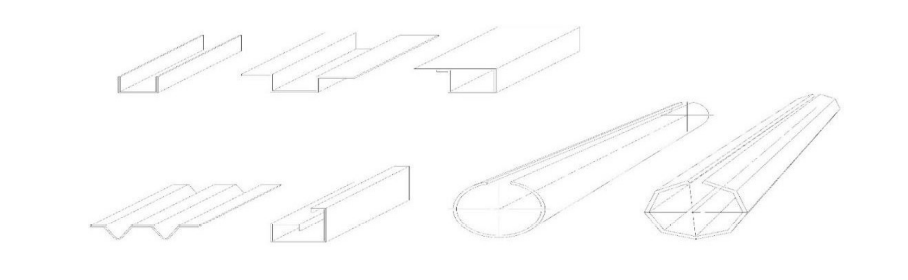

This machine is suitable for aircraft, shipbuilding, automobile, electrical appliances and other factories, construction, decoration and other industries, and the production of light poles. When bending sheets of different thicknesses, you only need to select the "V" groove bottom molds with different opening sizes. Generally, the selected opening is 8-10 times thickness of the plate. For example, when bending a 6mm plate, a 48-60mm slot can be used.

This machine adopts hydraulic transmission, which is stable and easy to operate. The table is provided with a mechanical deflection compensation mechanism to ensure a high geometric accuracy over the entire bending length.

C、Product outline structure

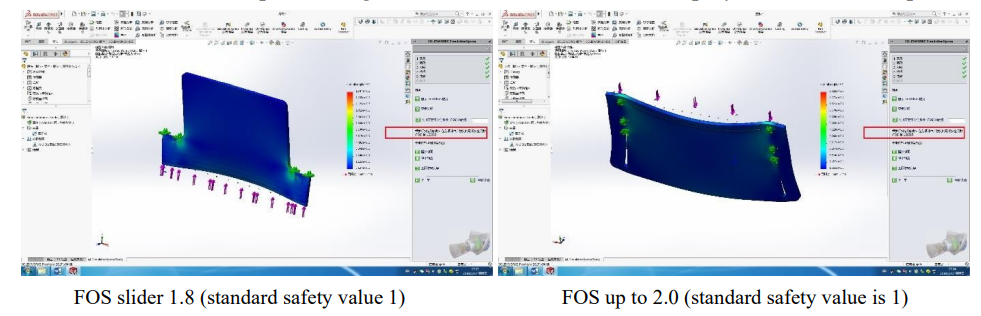

1. Using Solidworks (SimulationXpress) analysis method, optimized design by computer, beautiful appearance.

2. The machine adopts a steel plate welding structure with sufficient strength and rigidity. The hydraulic transmission ensures that no serious overload accidents are caused due to changes in sheet thickness or improper selection of the "V" shaped groove of the lower mold. In addition, the machine has a stable operation. Easy to operate, low noise, safe and reliable.

3. There is a mechanical stop in the oil cylinder to ensure the repeated positioning accuracy of the slider to the bottom dead center, so as to ensure the consistency of the bending angle during mass production.

4, using German technology for internal stress relief.

5. The whole frame adopts standing method to remove rust, and is sprayed with anti-rust paint.

D、Product outline structure

1. Using Solidworks (SimulationXpress) analysis method, optimized design by computer, beautiful appearance.

2. The machine adopts a steel plate welding structure with sufficient strength and rigidity. The hydraulic transmission ensures that no serious overload accidents are caused due to changes in sheet thickness or improper selection of the "V" shaped groove of the lower mold. In addition, the machine has a stable operation. Easy to operate, low noise, safe and reliable.

3. There is a mechanical stop in the oil cylinder to ensure the repeated positioning accuracy of the slider to the bottom dead center, so as to ensure the consistency of the bending angle during mass production.

4, using German technology for internal stress relief.

5. The whole frame adopts standing method to remove rust, and is sprayed with anti-rust paint.

E. Working slider structure

1、This machine adopts hydraulic and electrical control, the stroke of the slider can be adjusted arbitrarily, and it has jog, semi-automatic, automatic and other action specifications. The jog specification can be used for simple test and adjustment.

2、The design of the upper-type bending machine, the double cylinders work at the same time, the operation is balanced, convenient and safe.

3. There is a hold pressure delay function at the bottom dead point to ensure the accuracy of the workpiece.

4. Under the relevant national standards, the accuracy of the bending angle can reach ± 45 '.

5. With the function of slow-down control, the operator can control the workpiece better .

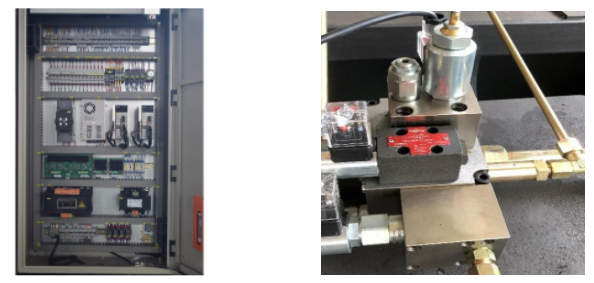

F、 Hydraulic system

1、The hydraulic system can realize the rapid descending of the slider, the slow descending, the bending of the working speed, the fast return stroke and the upward and downward movement of the slider.

2、Oil pump adopts gear pump, which can withstand high pressure and low noise.

3、Selection of high-quality seals, good sealing performance, reliable operation and long life.

4、The machine tool can work continuously under the rated load, the hydraulic system is leak-free and

continuously stable with high accuracy.

G、 Electrical control system

1、Electrical components and material meet international standards, safe and reliable, long life, strong anti-interference ability.

2、removable foot switch operation.

3、The electronic control components are made of high-quality brand-name products.

4 、 The machine tool fits AC 380V three-phase four-wire power supply, and the control circuit fits AC 220V voltage.

5、The main circuit of the motor is protected against short circuit, overload and phase loss.

6、The operation buttons are installed on the button table of the machine tool, electrical switches, indicators, installation and special electrical control boxes.

7、The oil pump stop button also serves as the master button of the machine tool. When the oil pump stops working, the entire machine tool stops working.

8、The machine is equipped with corresponding jog control buttons and emergency stop buttons.

H. Back gauge

The back gauge is driven by a servo motor through a synchronous belt and a synchronous wheel to drive the ball screw. The back gauge is supported by four linear guides. It has high repeated positioning accuracy, reliable structure, fast positioning speed, low noise and vibration, and high bearing capacity. The standard R-axis ascends and descends as a whole, which has a great advantage when bending complex workpieces, and it covers the transmission part with a safety cover, which is multi-effect.

Mold (Annex 1, Annex 2)

1、 The connecting part of the upper mold is equipped with a compensation mechanism to compensate the winding of the table and the slider when bending the sheet to ensure high working accuracy.

2. The lower mold is equipped with high-standard CNC concentric molds as standard to improve the overall accuracy, bending efficiency and mold life.

3. The lower working table has a hydraulic winding automatic compensation mechanism, which realizes that The blind area is effectively compensated, and high bending accuracy to ensure long-term stability. (Optional)

J、Fixture

1. The new two-stage imitation drop-out clip is adopted. The clip has many advantages such as high accuracy, high accuracy of multiple pieces, high-end appearance and safety identification.

2. The clamping mold is simple, and at the same time, it has a safety buckle. When disassembling and disassembling the small-sized mold, the worker can prevent the mold from falling off and being damaged due to misoperation and other safety accidents caused by falling off.

3. Special customers can choose double-sided clips.

L、DA53 Press Brake CNC System Basic Functions

1. "Shortcut key" touch navigation

2.10.1 " high resolution color TFT display

3.Up to 5 axis control (Y1, Y2, X + 2 auxiliary axes)

4. Deflection compensation control

5. Have mold / material / product library

6. Support servo or frequency conversion control

7. Advanced Y-axis control algorithm can control both closed-loop valve and open-loop valve.

8. USB peripheral interface.

1.Quality Control

Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery.

2.OEM Service

Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required.