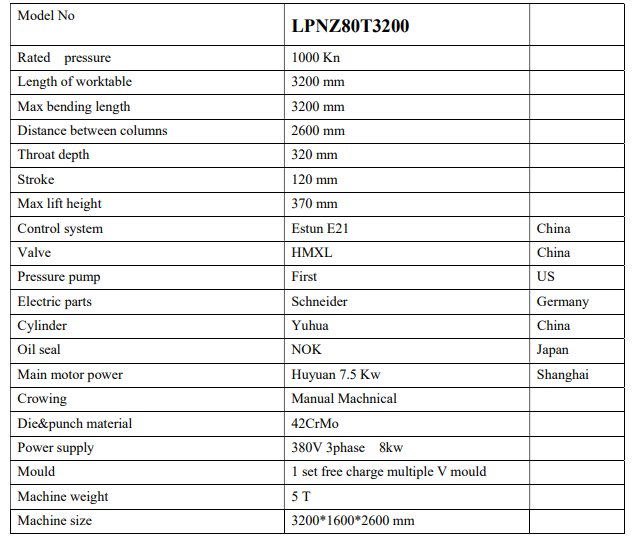

Hydralic Bending Machine

Model No.: LPNZ80T3200

Technical details

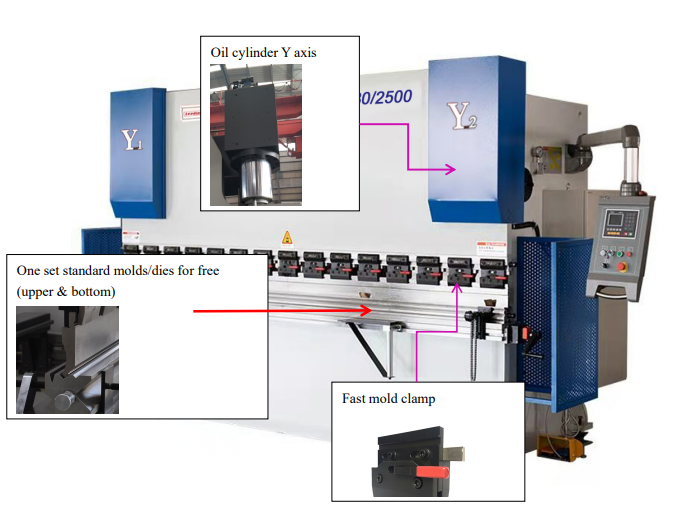

Structure featuers:

1. Adopt UG (finite element) analysis computer aid design, sturcture stable .

2. The machine structure is welded with steel plate, with sufficient strength and rigidity. The hydraulic drive prevents the machine from serious overload operation accidents caused by the change of sheet thickness or bad choice of lower die

cavity. Additionally, this machine is also featured by the steadiness of work, convenience of operation, and reliable safety.

3.The mechanic block is equipped in the oil cylinder to ensure the fixing accuracy when the slider travels to the bottom dead point and so as to assure the consistency of bending angle in bulking production.

4.Overall annealing processed to eliminate internal stress.

5.Entire frame using striking grit to get rid of rust and spout anti-corrosive paint.

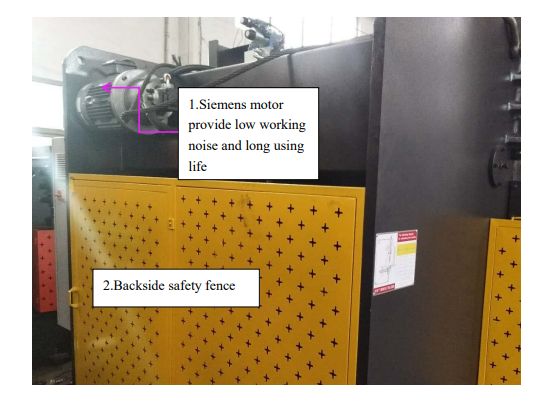

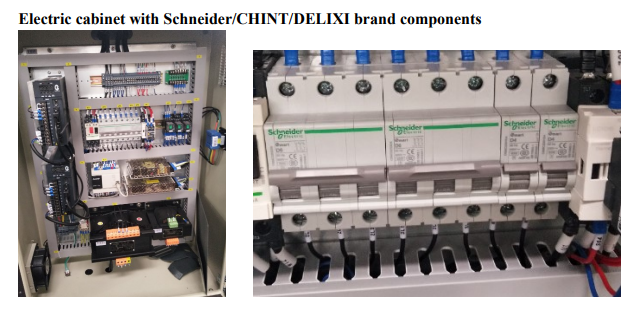

Electrical control system:

1.Electric components and material are accord with international standard, safety and reliable, long life, and strong anti jamming capability.

2.Movable footpad equiped.

3.Choosing high grade famous electrical control components.

4.Main power supply of motor has short circuit, overload, phase missing protection.

5.Operation buttons equipped on machine button stage, electric switch,pilot lamp equipped in electric box

6. Oil pump stop button as the total button of machine, when oil pump power off, whole machine stops working.

7.The synchronization of the slider travel of bending machine is mechanic synchronous unit in simple, stable and reliable structure with synchronous precision required by this machine. And generally, it can be woring for long time no maintainence required.

E21 CNC Controller feature:

Most pupular and stable bending machine control system. Multi back gauge and block controling. Control for general AC motors frequency inverter. Intelligent positioning. Holding/decompression time adjustable. Program memory of upto 40 programs up to 25steps per program. Single side positioning . Retract function . One Key backup/restore of parameters . Mm/inch 2 type unit optional.

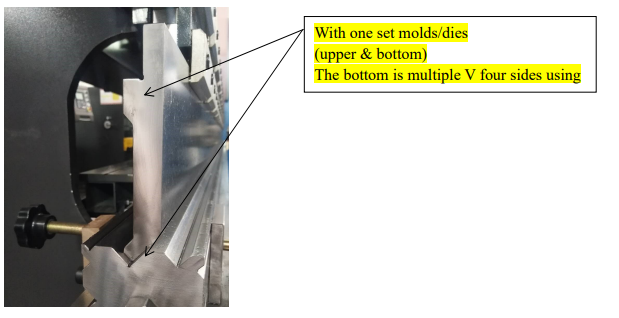

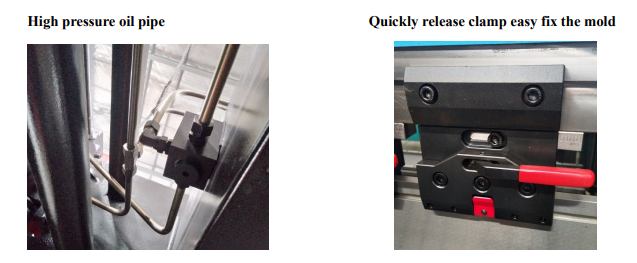

Free charge molds/dies:

1. One set of free charge upper and bottom die attached with machine.

1.Quality Control

Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery.

2.OEM Service

Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required.