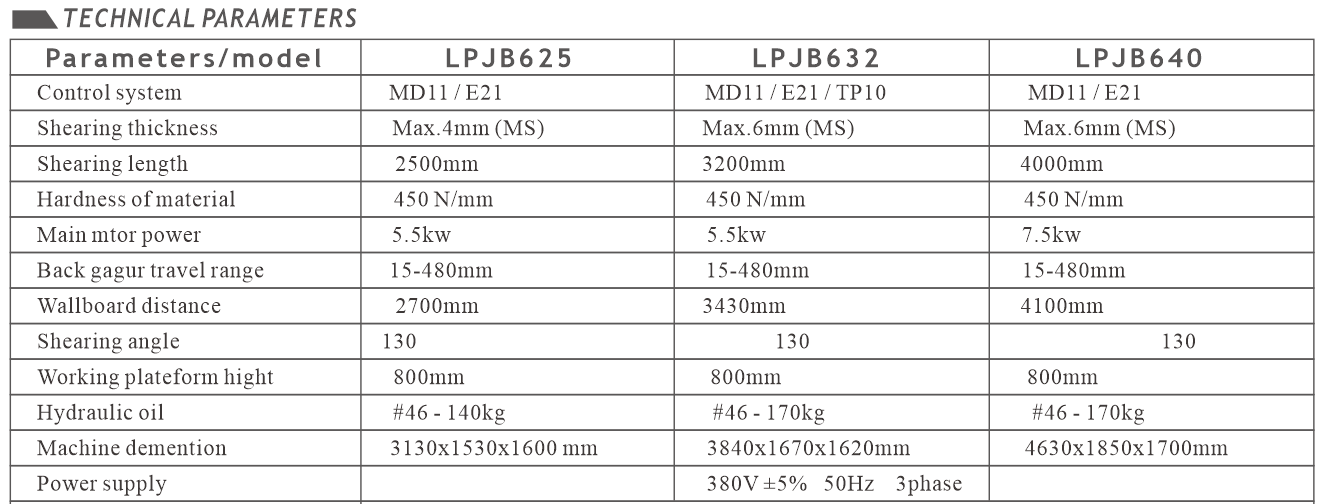

NC HYDRAULIC SHEARING MACHINE

Model No.: LPJB625

The shearing machine adopts trandition mechanical working type, for thin metal sheet cutting have its unique advantates like as high speed, low runing cost, free of maintenance, easy operation etc. adopts hydralic system as driving source, low noise and suitable run stably for long time, no consume parts required, its a good auxiliary option for sheet metal processing industry.

Shearing machine is more widely used in machining a shearing equipment, it can cut all kinds of thickness of the steel plate materials. Commonly used shearing machine is divided into pendulum and brake type two kinds. Pendulum shearing machine is use more. Operating mode is with pedal or buttons control for single or continuous cutting metal.

1. Hydraulic transmission, tilting head, frame welding whole durable, smooth use accumulator cylinder return quickly.

2. Has the function of stepless stroke has two blade on the knife, the knife has four blade, blade handle interval adjustment, upper and lower blade blade gap uniformity is easy to adjust.

3. Fencing and electric interlock to ensure safe operation.

4. Mixer machine tool holder adopts independent hydraulic pressure loading device, at the end of each pressure device have the rubber mat.

5.Using MD11 behind CNC system, shear frequency has a digital display.Mixer scroll device in reducing friction at the same time, also can keep the surface from scratch.

6. All steel welded structure, vibration to eliminate stress, strength good, strong rigidity.

7. The hydraulic transmission type, stable and reliable.

Retainer before shearing machine

Shear feeding process for sheet metal support role to reduce friction

Behind plate shears

Double screw XY adjustable design, location is more convenient and flexible

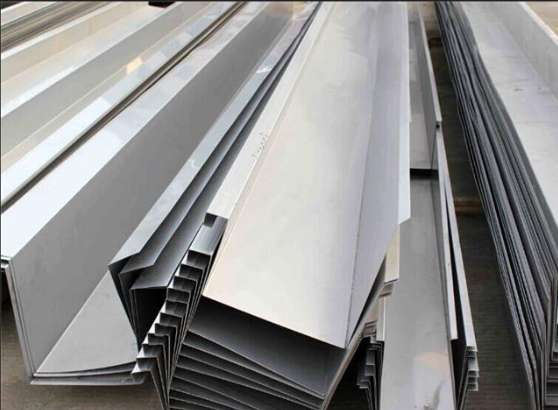

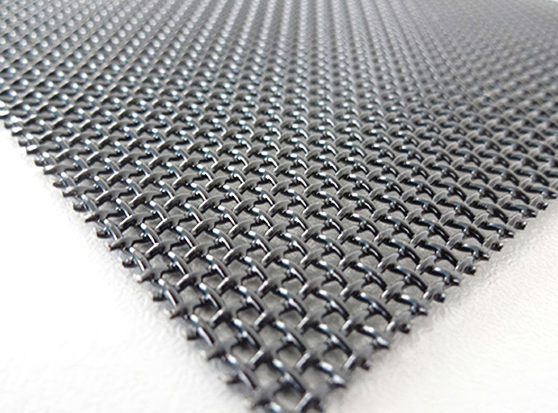

Scope of application

Suitable for iron plate, aluminum plate, king kong mesh, stainless steel plate, electrical cabinets, stainless steel doors and Windows, decorative strips, etc

1.Quality Control

Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery.

2.OEM Service

Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required.